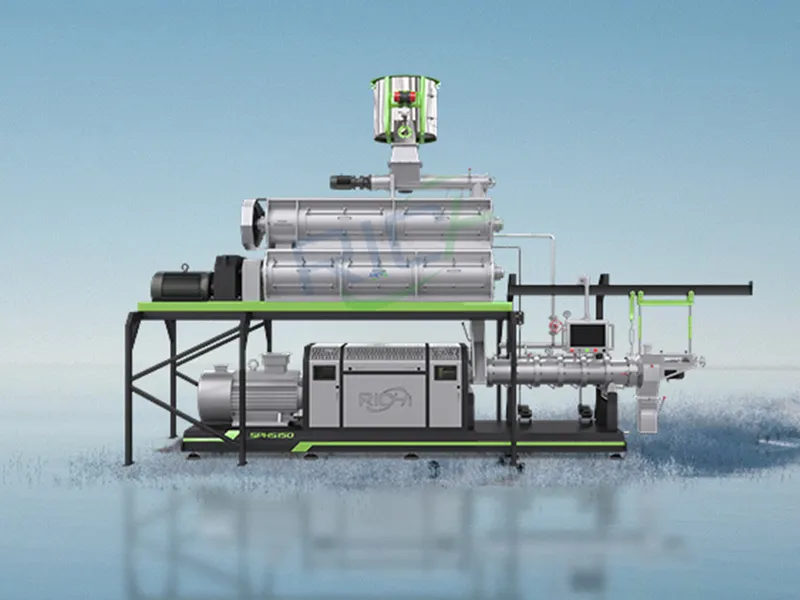

In the modern feed processing industry, the feed extruder machine from RICHI Pellet Machine has become an indispensable core piece of equipment, especially for producing high-value feeds such as aquatic feed and pet food. With its unique high-temperature and high-pressure extrusion technology, it not only optimizes the nutritional value of feed but also enhances production efficiency, enabling feed manufacturers to gain a competitive advantage in the market. This article provides a comprehensive introduction to the working principle, core advantages, main applications, and key purchasing considerations of the feed extruder machine, enabling you to gain a thorough understanding of this essential equipment.

What is a Feed Extruder Machine? Working Principle Explained

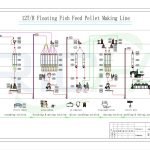

A feed extruder machine is a professional mechanical device that uses high-temperature, high-pressure steam and screw extrusion to mature, sterilize, and expand feed raw materials, ultimately forming granular feed of specific shapes. Its core working principle is screw extrusion expansion technology, which can be divided into the following key steps:

Material Conditioning: First, the mixed powdery feed raw materials enter the conditioner, where they are fully mixed with steam to absorb moisture and heat up for pre-maturation. This step lays the foundation for subsequent extrusion and expansion.

High-Temperature & High-Pressure Extrusion: The conditioned materials are sent to the extrusion chamber of the extruder. Inside the chamber, one or two rotating screws (single-screw or twin-screw) generate strong extrusion, shearing, mixing, and friction effects on the materials through their specific pitch and structure. At the same time, the steam injection system injects high-temperature and high-pressure steam into the chamber, so that the materials are subjected to high temperature (up to 110-200℃) and high pressure (up to dozens of atmospheres) under the combined action of mechanical energy and thermal energy.

Material Maturation & Plasticization: Under the high-temperature and high-pressure environment, the starch in the materials is gelatinized, proteins are denatured, and the materials are fully matured and sterilized, eventually presenting a molten plasticized state.

Instant Expansion & Molding: The molten materials are forced to be extruded through the molding die (die head) at the end of the extrusion chamber. When the materials are extruded from the die holes, the pressure drops to normal pressure in an instant, and the moisture in the materials evaporates rapidly, causing the material volume to expand rapidly (up to several times or even ten times the original volume), forming puffed granular feed with a porous and loose structure.

Welcome to view:https://pelletmakingmachine.com/floating-fish-feed-extruder-machine/

Core Advantages of Feed Extruder Machine: Why It’s Essential for Feed Mills

Compared with traditional feed processing equipment, the feed extruder machine from RICHI Pellet Machine has obvious advantages in improving feed quality, ensuring animal health, and reducing production costs. Its core advantages are as follows:

Improve Feed Digestibility & Nutritional Value: The high-temperature and high-pressure environment promotes the full gelatinization of starch and moderate denaturation of proteins, making nutrients easier for animals to digest and absorb. At the same time, the extrusion process can reduce anti-nutritional factors (such as trypsin inhibitors) in raw materials, further enhancing the nutritional value of feed.

Thorough Sterilization, Reducing Disease Risks: The high temperature (110-200℃) and high pressure during the extrusion process can effectively kill pathogenic microorganisms such as Salmonella and Escherichia coli in raw materials, as well as harmful enzymes. This greatly reduces the risk of animal diseases caused by feed and improves the survival rate of breeding.

Excellent Water Stability, Reducing Waste & Pollution: The puffed feed produced by the feed extruder machine has good water stability, especially suitable for aquatic feed. It can stay in water for a long time without dissolving, reducing the loss of nutrients and the pollution of water quality, and at the same time reducing the feed waste of aquatic animals.

Wide Raw Material Adaptability & Product Diversification: The feed extruder machine can handle a variety of raw materials, including high-fat, high-fiber, and difficult-to-pellet raw materials. By replacing different molds, it can produce granular feeds of various shapes (cylindrical, spherical, square, etc.) and sizes, meeting the needs of different animals (aquatic products, pets, special animals, young livestock).

Extend Feed Storage Period: After extrusion, the feed has low moisture content (needs to be dried subsequently), which is not easy for microorganisms to multiply, thus extending the storage period of the feed and reducing the loss caused by feed deterioration.

Main Applications of the Feed Extruder Machine

With its excellent performance, the feed extruder machine is widely used in various fields of the feed industry, covering aquatic feed, pet feed, special animal feed, and other fields.

Aquatic Feed Production: This is the most important application field of the feed extruder machine. It can produce floating, slow-sinking, and sinking feeds for fish, shrimp, crabs, and other aquatic products. The puffed aquatic feed has good palatability and high digestibility, which can promote the rapid growth of aquatic products and improve the breeding benefit.

Pet Feed Production: 0.3-2T/H pet food extruder is used to produce dry granular feeds such as cat food and dog food. The extrusion process gives the pet feed a crispy taste and good appearance, which is popular with pets. At the same time, it is easy to store and can meet the nutritional needs of different breeds and growth stages of pets.

Special Animal Feed Production: Suitable for producing feeds for fur animals (minks, foxes), experimental animals, ornamental animals, etc. These animals have special nutritional requirements, and the feed extruder machine can realize the precise matching of nutrients through flexible formula adjustment.

Young Livestock Feed Production: Producing starter feeds for piglets, calf feeds, etc. The puffed young livestock feed is easy to digest and absorb, which can reduce the digestive tract diseases of young livestock and improve the survival rate and growth performance.

Feed Raw Material Puffing: Puffing raw materials such as full-fat soybeans and corn to improve the utilization rate of oil and starch. Puffed raw materials can be used as high-quality ingredients in various feeds.

Key Considerations for Buying a Feed Extruder Machine

Choosing a suitable feed extruder machine from RICHI Pellet Machine is crucial to improving production efficiency and feed quality. When purchasing, you need to comprehensively consider the following core factors:

Production Capacity: The production capacity (tons per hour) is the core indicator of the equipment specification. It is necessary to select the corresponding model according to the actual production scale to avoid resource waste caused by excess capacity or production bottlenecks caused by insufficient capacity.

Screw Type: There are two types of single-screw and twin-screw. Single-screw extruders are mainstream, with low cost and suitable for small and medium-sized feed factories; twin-screw extruders have better mixing and shearing effects, strong ability to handle complex raw materials, but higher cost, suitable for large-scale feed factories producing high-end feed (such as pet food with high meat slurry content).

Puffing Degree & Maturation Degree: These two indicators directly affect the quality of feed. It is necessary to choose equipment that can stably achieve the target puffing degree and maturation degree to ensure the digestibility and nutritional value of feed.

Energy Consumption & Energy Saving Performance: The feed extruder machine is a high-energy-consuming piece of equipment. When purchasing, you should pay attention to parameters such as motor power and thermal efficiency, and give priority to products with advanced energy-saving technologies to reduce long-term operating costs.

Stability & Reliability: The equipment needs to withstand high temperature, high pressure, and material wear during long-term operation. It is necessary to check the structural design, material selection, and manufacturing process of the equipment, and choose brands and models with proven market performance and good reputation.

Automation Level: Advanced feed extruder machines are equipped with PLC automatic control systems, which can realize precise adjustment of feeding amount, steam amount, temperature, pressure, and other parameters, and support remote monitoring and fault early warning. A high automation level can reduce human operation errors and improve production efficiency.

Mold System: Pay attention to the convenience of mold replacement, the range of pore sizes, and the selection of pore types. A flexible mold system can meet the production needs of different types of feed.

After-Sales Service: Perfect after-sales service (such as installation guidance, operation training, spare parts supply, maintenance support) is an important guarantee for the stable operation of the equipment. It is necessary to choose suppliers with complete after-sales service systems.

Conclusion

As the core equipment of modern feed production, the feed extruder machine from RICHI Pellet Machine has irreplaceable advantages in improving feed quality, ensuring animal health, and expanding production capacity. Whether it is a large-scale feed group or a small and medium-sized breeding farm, choosing a suitable feed extruder machine can effectively improve economic benefits. When purchasing, it is necessary to comprehensively consider factors such as production capacity, screw type, performance indicators, and after-sales service to select equipment that matches the actual needs.

If you want to know more about the model selection, price, and technical parameters of the feed extruder machine, welcome to contact us. Our professional team will provide you with customized solutions and high-quality services.(see post)