1. Introduction: The Growing Importance of Fish Feed

Aquaculture has emerged as one of the fastest-growing sectors in global food production. As the demand for seafood continues to rise, efficient and sustainable fish farming practices are essential. A fish feed processing line plays a pivotal role in this ecosystem, ensuring that fish receive balanced nutrition to grow healthily while optimizing production efficiency.

Fish feed is no longer just a basic supplement; it represents a critical component of modern aquaculture, combining science, technology, and sustainability. By using formulated feeds instead of raw grains or natural food, farmers can improve growth rates, reduce mortality, and enhance overall farm profitability. Countries across Asia, Africa, and South America are investing in fish feed production lines to meet both local consumption and export demand.

2. Historical and Cultural Context of Aquaculture

Fishing has been a fundamental human activity for thousands of years, providing protein and sustenance to communities worldwide. Traditional aquaculture often relied on natural feed sources, such as algae, plankton, and agricultural by-products. However, as fish farming shifted from small-scale ponds to commercial operations, the need for balanced, nutrient-rich feed became evident.

Modern fish feed production reflects both technological advancement and cultural adaptation. In regions where aquaculture is culturally significant, such as Southeast Asia, Europe, and parts of Africa, specialized feed ensures that traditional fish species like tilapia, catfish, carp, and salmon thrive under commercial farming conditions. The introduction of fish feed production lines represents the intersection of centuries-old fishing traditions with contemporary industrial practices.

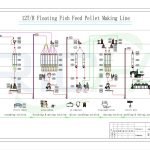

3. Components of a Fish Feed Production Line

A standard fish feed production line consists of several critical components that work in a coordinated process:

Raw Material Grinder: Reduces grains, soy meal, fish meal, and other ingredients into fine powder suitable for mixing.

Mixer: Ensures uniform blending of nutrients, vitamins, and minerals to produce balanced feed.

Extruder or Pelletizer: Compresses the feed into floating or sinking pellets depending on fish species and feeding behavior.

Dryer: Reduces moisture content to improve storage stability.

Cooling System: Prevents pellet breakage and maintains pellet quality.

Packaging System: Prepares feed for storage, sale, or transport.

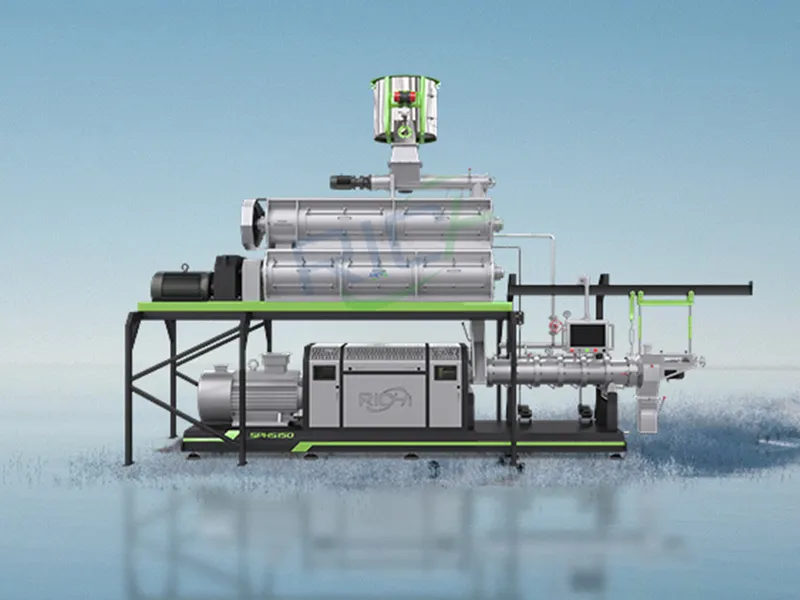

Advanced fish feed production lines often incorporate automated monitoring, quality control systems, and adjustable parameters for pellet size, density, and nutrient composition. Companies like RICHI offer modular solutions that cater to different farm scales, ensuring flexibility and efficiency in production. https://richipelletizer.com/fish-feed-mill-plant-cost/

4. Advantages of Using a Fish Feed Production Line

The adoption of a fish feed production line offers multiple benefits for modern aquaculture:

Balanced Nutrition: Formulated feeds provide essential proteins, fats, vitamins, and minerals for optimal fish growth.

Efficient Feeding: Floating or sinking pellets allow for controlled feeding, reducing waste and water pollution.

Consistent Quality: Automated production ensures uniform pellet size and nutrient content.

Scalability: From small farms to large industrial operations, production lines can be adjusted to match capacity needs.

These advantages make automated feed production indispensable for both economic and environmental sustainability. By minimizing waste and improving feed conversion ratios, fish farmers achieve higher yields without compromising ecological balance.

5. Technological and Environmental Considerations

Producing high-quality fish feed requires careful attention to both technology and environmental impact. Moisture levels, ingredient composition, and pellet density must be precisely controlled. Overly wet pellets may spoil quickly, while overly dense pellets may sink too fast for surface-feeding species.

Modern lines, including those provided by RICHI, integrate advanced extrusion technology and drying systems to maintain pellet integrity and nutrient preservation. Furthermore, environmentally responsible production practices are essential. By using locally sourced raw materials and optimizing energy efficiency, fish feed production lines contribute to sustainable aquaculture practices.

6. Economic and Market Significance

Aquaculture contributes significantly to global food security and economic growth. A fish feed production line not only supports efficient farming but also stimulates local economies by creating jobs, reducing feed import dependency, and encouraging small- to medium-sized farm development.

Internationally, the fish feed market continues to expand, driven by the rising demand for tilapia, catfish, salmon, and other popular farmed species. Producers who operate reliable, high-capacity production lines can meet both domestic and export market demands, ensuring long-term profitability. Understanding the investment in such lines is critical, as it balances operational efficiency, production capacity, and feed quality.

7. Choosing the Right Fish Feed Production Line

Selecting the appropriate fish feed production line involves several considerations:

Scale of Operation: Small-scale farms may require 0.5–1 ton per hour capacity, while large industrial farms need 5–20 tons per hour.

Feed Type: Floating, sinking, or extruded feed depending on the target species.

Automation Level: Advanced monitoring and control improve production efficiency and consistency.

Supplier Reliability: Working with trusted suppliers such as RICHI ensures technical support, quality assurance, and maintenance guidance.

By carefully evaluating these factors, aquaculture entrepreneurs can maximize productivity and minimize operational risks. A well-chosen production line contributes to both profitability and environmental sustainability. Helpful site

8. Cultural and Nutritional Significance

Fish farming is not only an economic activity but also a cultural and nutritional cornerstone in many regions. Seafood provides essential proteins, omega-3 fatty acids, and micronutrients vital for human health. By producing high-quality feed through a fish feed production line, farmers can improve growth rates and ensure consistent fish quality, meeting both consumer demands and regulatory standards.

Furthermore, modern production lines allow for customized nutrient formulations tailored to local fish species and farming conditions. This integration of science, culture, and technology exemplifies the evolving nature of aquaculture as a sustainable food source.

9. Conclusion: A Strategic Investment in Sustainable Aquaculture

Investing in a fish feed production line represents more than a technological upgrade—it is a commitment to sustainable, efficient, and profitable aquaculture. With the support of modern technology and reliable suppliers like RICHI, producers can ensure high-quality feed production, meet growing market demand, and contribute to environmentally responsible fish farming practices.

As global populations continue to rise and seafood demand grows, well-managed production lines will remain central to sustainable aquaculture development, providing economic, cultural, and ecological benefits for generations to come. Floating Fish Feed Production Line In Uzbekistan